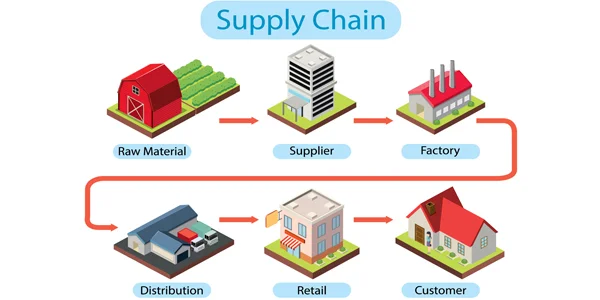

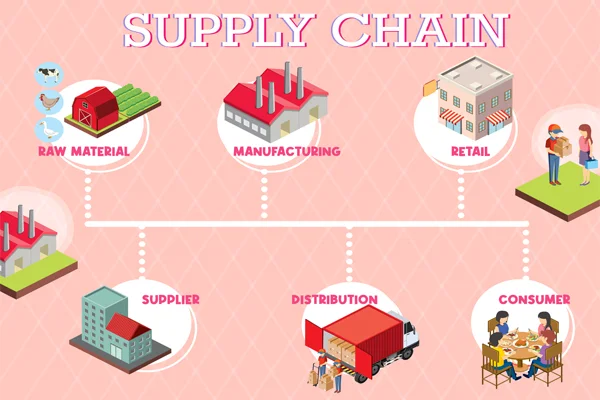

Supply Chain: The Future of Trust, is a network of organizations, people, activities, information, and resources involved in the production, distribution, and delivery of goods and services to consumers or end-users. It encompasses all the processes and activities required to bring a product or service from its initial conception and raw material sourcing to its final consumption by customers.

History of Supply Chain

The history of supply chain management is a story of evolution and adaptation to changing business practices, technologies, and global economic conditions. It can be traced back to ancient times when people engaged in trade and commerce.

Here is a brief overview of the key developments in the history of supply chain management:

- Ancient Trade Routes: Supply chains have existed for thousands of years, as early civilizations engaged in trade through various routes, such as the Silk Road and the Mediterranean Sea. These routes facilitated the exchange of goods and raw materials over long distances.

- Industrial Revolution (Late 18th to 19th Century): The advent of the Industrial Revolution marked a significant shift in supply chain management. Mass production, powered by steam engines and later electricity, led to the need for more organized and efficient supply chains to source raw materials and distribute finished products.

- Railroads and Telegraphs: The development of railroads and telegraph networks in the 19th century allowed for faster transportation and communication. This innovation improved the coordination and management of supply chains across larger geographical areas.

- Early 20th Century: The early 20th century saw the emergence of concepts like Scientific Management, which aimed to optimize manufacturing and assembly processes. This laid the foundation for more systematic supply chain practices.

- Post-World War II: After World War II, supply chain management began to gain more prominence as businesses sought greater efficiency and economies of scale. Concepts like Just-In-Time (JIT) and Total Quality Management (TQM) were introduced to reduce waste and improve product quality.

- Globalization: The latter half of the 20th century saw increased globalization, with companies sourcing raw materials and components from around the world. This necessitated the development of more complex and global supply chains.

- Information Technology: The advent of computers and information technology in the latter part of the 20th century revolutionized supply chain management. It enabled better tracking of inventory, demand forecasting, and communication between supply chain partners.

- E-commerce and Internet: The rise of e-commerce and the internet in the late 20th and early 21st centuries further transformed supply chains. Online retail and digital platforms created new distribution and fulfillment models.

- Supply Chain Resilience: In the 21st century, supply chain resilience gained importance as companies sought to manage risks associated with natural disasters, geopolitical events, and disruptions.

- Sustainability: Sustainability and environmental concerns have become critical factors in supply chain management. Companies are now looking to reduce their carbon footprint and adopt more sustainable practices throughout their supply chains.

- Modern Challenges: Today, supply chain management faces new challenges such as the global COVID-19 pandemic, trade tensions, and the rapid evolution of technology, including the use of data analytics, AI, and automation to enhance efficiency and decision-making.

The history of supply chain management is characterized by a continual evolution in response to changing economic, technological, and global conditions. It has become an integral part of modern business strategy, focusing on efficiency, optimization, and risk management.

Types of Supply Chain

Supply chains can vary significantly depending on the type of industry, the nature of products or services being provided, and the specific business model of an organization. There are several different types of supply chains, each designed to meet the unique needs and challenges of different sectors and businesses.

Here are some common types of supply chains:

- Linear Supply Chain: This is the most traditional and basic form of a supply chain, where goods move from suppliers to manufacturers to distributors and then to retailers before reaching consumers. It follows a sequential path.

- Extended Supply Chain: In this type, the linear supply chain is extended to include suppliers’ suppliers and customers’ customers. It involves a broader network and deeper integration of partners.

- Agile Supply Chain: Agile supply chains are designed for industries where customer demands are highly uncertain or where customization and quick response are critical. They are flexible and responsive to changing market conditions.

- Lean Supply Chain: Lean supply chains focus on reducing waste, minimizing inventory levels, and improving efficiency. They aim to provide products or services with minimal resources.

- Responsive Supply Chain: A responsive supply chain is adaptive to changes in customer demand. It may hold some safety stock to respond quickly to fluctuations in demand.

- Green Supply Chain: These supply chains prioritize sustainability and environmental responsibility. They aim to minimize the ecological impact of the supply chain’s operations.

- Circular Supply Chain: Circular supply chains focus on recycling, reusing, and repurposing materials and products to minimize waste and promote a more sustainable approach.

- Global Supply Chain: These supply chains operate on a global scale, involving suppliers and partners from various countries. They face challenges related to international logistics, customs, and cultural differences.

- Omni-Channel Supply Chain: These supply chains are designed for businesses that sell products through multiple channels, such as physical stores, e-commerce, and mobile apps. They must ensure a consistent customer experience across all channels.

- Blockchain-Based Supply Chain: Some supply chains use blockchain technology to enhance transparency, traceability, and security in the movement of goods and data.

- Cold Chain: Cold supply chains are essential for the transportation and storage of temperature-sensitive products like food, pharmaceuticals, and vaccines. They must maintain specific temperature conditions throughout the supply chain.

- Reverse Supply Chain: This type of supply chain deals with the return, recycling, and disposal of products and materials. It is crucial for handling product returns, recycling, and waste management.

- Just-In-Time (JIT) Supply Chain: JIT supply chains focus on minimizing inventory and producing goods as close as possible to when they are needed. This reduces carrying costs and waste.

- Make-to-Order (MTO) Supply Chain: MTO supply chains produce goods only after receiving customer orders. This is common in custom manufacturing or certain types of artisanal products.

- Engineer-to-Order (ETO) Supply Chain: ETO supply chains are for highly customized, one-of-a-kind products. They involve designing and manufacturing products based on specific customer requirements.

- Continuous Flow Supply Chain: Continuous flow supply chains are typically found in industries with very high volumes, like the production of bulk commodities. They aim for constant, uninterrupted production and distribution.

The choice of the type of supply chain depends on the nature of the business, market conditions, customer demands, and the specific objectives and strategies of an organization. Many companies use a combination of these supply chain types or adapt their supply chain strategies as their business needs change.

Facts of Supply Chain

Supply chains are essential components of modern business operations, and there are many interesting facts and statistics related to them.

Here are some key facts about supply chains:

- Massive Economic Impact: Supply chains are a significant driver of the global economy. In the United States alone, supply chain activities account for over 37% of GDP.

- Global Reach: Supply chains have become increasingly globalized. Many products have components that come from different parts of the world before they are assembled and distributed.

- E-commerce Boom: The growth of e-commerce has led to the expansion of supply chains, with a focus on last-mile delivery and efficient fulfillment centers.

- Inventory Costs: Holding excess inventory can be costly. On average, inventory carrying costs can account for about 20-30% of the value of the inventory.

- Environmental Impact: Supply chains are a significant contributor to greenhouse gas emissions. In the U.S., transportation-related emissions from supply chains account for over a quarter of the country’s total emissions.

- Supply Chain Visibility: Many companies are investing in technology to improve supply chain visibility. About 75% of companies believe that supply chain visibility is essential for their business.

- Challenges in Pharmaceutical Supply Chains: The pharmaceutical industry faces unique supply chain challenges, including stringent regulatory requirements, temperature control for sensitive products, and counterfeiting concerns.

- Food Supply Chain Length: The average length of the food supply chain is around 1,500 miles, highlighting the complexity of ensuring the freshness and safety of food products.

- Resilience Concerns: The COVID-19 pandemic exposed vulnerabilities in global supply chains. Many companies are now reevaluating their supply chain strategies to build more resilient and flexible systems.

- Supply Chain Job Growth: The field of supply chain management offers promising career opportunities. Job growth in supply chain and logistics is expected to continue, driven by increased demand for skilled professionals.

- Reverse Logistics: Reverse logistics, which deals with product returns and recycling, has become a critical aspect of supply chains, as the e-commerce industry experiences high return rates.

- Digital Transformation: The adoption of technologies like AI, IoT, and blockchain is on the rise in supply chain management to improve efficiency and transparency.

- Bullwhip Effect: The bullwhip effect is a phenomenon where small fluctuations in demand can cause significant swings in inventory levels up the supply chain. It underscores the importance of accurate demand forecasting.

- Just-In-Time Inventory: The concept of Just-In-Time (JIT) inventory, pioneered by Toyota, has become a fundamental strategy for many industries to reduce waste and improve efficiency.

- Supply Chain Disruptions: Natural disasters, geopolitical tensions, and unexpected events like the COVID-19 pandemic can disrupt supply chains, emphasizing the importance of risk management.

- Ethical and Sustainable Supply Chains: Consumers are increasingly concerned about the ethical and environmental aspects of supply chains. Companies are responding by adopting more sustainable and transparent practices.

These facts illustrate the diverse and dynamic nature of supply chains, which play a critical role in the global economy and have a substantial impact on businesses and consumers alike.

Benefits of Supply Chain

Supply chains offer numerous benefits to businesses and consumers alike. These benefits include improved efficiency, cost savings, better customer service, and more.

Here are some of the key advantages of an effective supply chain:

- Cost Reduction: Efficient supply chain management helps minimize costs associated with inventory, transportation, warehousing, and production. This cost reduction can lead to higher profit margins for businesses.

- Improved Efficiency: Supply chains streamline operations, reducing lead times, eliminating waste, and optimizing resource allocation. This results in more efficient processes and operations.

- Better Customer Service: A well-managed supply chain ensures that products or services are available when and where customers need them. This leads to improved customer satisfaction and loyalty.

- Competitive Advantage: An effective supply chain can be a source of competitive advantage, as it allows businesses to respond more quickly to market changes and customer demands.

- Inventory Management: Supply chains help optimize inventory levels, reducing excess stock and the costs associated with carrying it, while ensuring products are available when needed.

- Risk Mitigation: Supply chain management allows businesses to diversify suppliers, hedge against price fluctuations, and develop contingency plans to reduce the impact of supply disruptions.

- Global Reach: Supply chains enable businesses to source materials and components from around the world, making it possible to access global markets and benefit from cost advantages in different regions.

- Innovation: Effective supply chain management can foster innovation through collaboration with suppliers and partners. This can lead to the development of new products and technologies.

- Environmental Responsibility: Sustainable supply chain practices reduce environmental impact through efficient transportation, reduced waste, and responsible sourcing, appealing to environmentally conscious consumers.

- Data-Driven Decision-Making: Modern supply chains often rely on data analytics to monitor and optimize operations, resulting in better decision-making and responsiveness to changes in demand and market conditions.

- Supply Chain Visibility: Improved visibility along the supply chain helps businesses track products, monitor quality, and respond to potential issues more effectively.

- Collaborative Relationships: Effective supply chains foster collaborative relationships with suppliers and partners, which can lead to mutually beneficial arrangements and long-term partnerships.

- Customizationand Personalization: Well-managed supply chains enable businesses to offer customized and personalized products or services to meet individual customer needs and preferences.

- Reduction in Lead Times: A streamlined supply chain can significantly reduce lead times, allowing businesses to respond more rapidly to market changes and customer orders.

- Regulatory Compliance: Compliance with regulations and standards is critical in many industries. Effective supply chain management helps ensure that products meet quality and safety standards.

- Continuous Improvement: The principles of continuous improvement and lean manufacturing are often integrated into supply chain management, resulting in ongoing optimization of processes.

- Operational Flexibility: An adaptable supply chain allows businesses to scale production up or down as needed, accommodating fluctuations in demand and market conditions.

Overall, a well-structured and effectively managed supply chain can help businesses thrive in a competitive market, improve operational efficiency, and deliver value to customers, while also contributing to the company’s bottom line.

What are the future of supply chain?

The future of supply chain management is marked by several emerging trends and developments driven by technological advancements, changing consumer expectations, and global challenges.

Here are some key aspects of the future of supply chain:

- Digital Transformation: The integration of advanced technologies such as artificial intelligence (AI), machine learning, big data analytics, and the Internet of Things (IoT) will continue to revolutionize supply chain operations. These technologies will enhance visibility, decision-making, and automation across the supply chain.

- Blockchain for Transparency: Blockchain technology is being increasingly adopted for its ability to provide transparency, traceability, and security in supply chains. It can help reduce fraud, counterfeiting, and errors in the tracking of goods.

- Sustainability and ESG: Environmental, Social, and Governance (ESG) considerations will play a significant role in supply chain strategies. Businesses will focus on sustainability, ethical practices, and reducing their carbon footprint to meet evolving consumer and regulatory demands.

- Resilience and Risk Management: The COVID-19 pandemic highlighted the need for more resilient supply chains. Organizations will invest in risk management strategies, diversifying suppliers, and building contingency plans to mitigate disruptions.

- Supply Chain Localization: A move towards shorter, more localized supply chains will reduce exposure to global risks and improve responsiveness to local demand. This could involve nearshoring or onshoring production and sourcing.

- Circular Supply Chains: Circular supply chains will focus on recycling, reusing, and repurposing materials and products to reduce waste and promote sustainability.

- Demand Forecasting and AI: AI-driven demand forecasting will become more accurate, allowing companies to better anticipate customer needs and optimize inventory levels and production accordingly.

- Personalization and Customization: Advanced manufacturing technologies, like 3D printing, will enable greater product personalization and customization, which will impact supply chain processes, especially in the production and distribution phases.

- Last-Mile Innovations: Innovations in last-mile delivery, such as autonomous vehicles, drones, and smart lockers, will continue to reshape the final stage of product delivery, improving efficiency and convenience.

- Collaborative Ecosystems: Supply chain partners will work closely together in collaborative ecosystems, sharing data, resources, and expertise to create more agile and responsive supply chains.

- Supply Chain Talent: There will be a growing demand for supply chain professionals with expertise in data analytics, technology, sustainability, and risk management.

- Regulatory Changes: Ongoing changes in trade regulations and tariff structures, as well as new regulations addressing supply chain transparency, will require companies to adapt and comply.

- Autonomous Supply Chains: Autonomous supply chains, driven by AI and automation, will become more prevalent, optimizing processes from end to end.

- Energy Efficiency: Supply chains will focus on reducing energy consumption and incorporating renewable energy sources to align with sustainability goals.

- Responsible Sourcing: The sourcing of materials and components from suppliers with ethical and sustainable practices will gain more attention, with consumers demanding transparency in product origins.

- Reskilling and Workforce Development: The workforce involved in supply chain management will require ongoing reskilling to adapt to new technologies and processes.

The future of supply chain management is dynamic and will continue to evolve as technology, consumer preferences, and global conditions change. Organizations that proactively adapt to these trends will be better positioned to thrive in the competitive and rapidly evolving supply chain landscape.

How has e-commerce impacted supply chains?

E-commerce has had a profound impact on supply chains, transforming the way products are sourced, distributed, and delivered.

Its influence on supply chains can be seen in several key ways:

- Changing Consumer Expectations: E-commerce has conditioned consumers to expect faster delivery, greater convenience, and more product choices. This has put pressure on supply chains to become more agile and responsive.

- Last-Mile Delivery: E-commerce has led to increased demand for efficient last-mile delivery services, pushing supply chains to invest in technologies such as drones, autonomous vehicles, and smart lockers to improve delivery speed and convenience.

- Globalization of Supply Chains: E-commerce has enabled businesses to reach a global customer base, which has necessitated the globalization of supply chains. Products are sourced from different regions and shipped worldwide, creating a need for more complex and efficient international logistics.

- Inventory Management: E-commerce has led to changes in inventory management strategies. Companies may maintain smaller inventories due to the ability to restock more frequently. However, it also requires more accurate demand forecasting to avoid stockouts.

- Supply Chain Visibility: E-commerce businesses place a high emphasis on supply chain visibility. They use technology to track the movement of products in real-time, which helps them manage inventory, respond to customer inquiries, and optimize operations.

- Direct-to-Consumer (DTC) Models: Many brands have adopted DTC models, which involve selling products directly to consumers through e-commerce channels. This eliminates the need for intermediaries, giving companies more control over their supply chains.

- Reverse Logistics: E-commerce’s higher return rates have made reverse logistics (the process of handling product returns) a crucial aspect of supply chains, requiring efficient systems for processing returns and re-stocking returned items.

- Multi-Channel Sales: E-commerce businesses often sell through multiple channels, including their website, marketplaces (e.g., Amazon, eBay), and physical stores. This necessitates integrating these channels into a cohesive supply chain.

- Demand Forecasting: Accurate demand forecasting is vital in e-commerce to avoid overstocking or stockouts. Advanced analytics and AI are used to predict customer demand and optimize inventory levels.

- Sustainability Considerations: E-commerce companies are increasingly focusing on sustainable supply chain practices, such as reducing packaging waste and carbon emissions, in response to consumer demand for eco-friendly options.

- Data-Driven Decision-Making: E-commerce relies on data analytics to gain insights into customer behavior, improve the customer experience, and optimize supply chain operations. Real-time data and analytics drive decision-making in areas like pricing, inventory, and marketing.

- Supply Chain Disruption Management: E-commerce businesses have had to become adept at managing supply chain disruptions, such as those caused by natural disasters, geopolitical events, or global health crises like the COVID-19 pandemic.

- Customer-Centric Supply Chains: E-commerce has shifted the focus of supply chains from being product-centric to customer-centric. It emphasizes delivering the right products to customers at the right time and place.

In summary, e-commerce has accelerated the evolution of supply chains, making them more flexible, customer-focused, and technology-driven. It has pushed companies to adopt innovative strategies and technologies to meet the demands of today’s online shoppers and to remain competitive in an increasingly digital marketplace.

Internet of Things: (IoT) Benefits & Building The Urban Future