3D Printing Technology, also known as additive manufacturing, is a manufacturing process that creates three-dimensional objects by layering material on top of itself. It is a revolutionary technique that has gained widespread use across various industries due to its versatility and capabilities. Here’s a comprehensive definition:

3D printing technology is a process of creating physical objects from digital models by depositing material layer by layer, typically in a bottom-up fashion, to build a final three-dimensional object. This technology relies on computer-aided design (CAD) software to create a virtual representation of the desired object, which is then sliced into thin horizontal cross-sections or layers. The 3D printer, guided by these digital instructions, adds material one layer at a time, solidifying or bonding it together to construct the final object. The materials used in 3D printing can range from plastics and metals to ceramics and even organic materials like biomaterials and food.

History of 3D Printing Technology

The history of 3D printing technology dates back several decades and has evolved from experimental processes into a transformative manufacturing technology.

Here is a brief overview of the key milestones and developments in the history of 3D printing:

- 1960s – Inception of Stereolithography (SLA): The foundation of 3D printing can be traced back to the 1960s when Chuck Hull, an American engineer, developed the first 3D printing technology known as stereolithography (SLA). Hull’s invention involved using a UV laser to solidify layers of liquid photopolymer resin.

- 1980s – Fused Deposition Modeling (FDM): In the mid-1980s, Scott Crump, another American engineer, created the Fused Deposition Modeling (FDM) technology. FDM is based on extruding thermoplastic material layer by layer to build an object. This technology eventually became one of the most popular forms of 3D printing.

- 1990s – Commercialization and Patenting: During the 1990s, 3D printing technologies started to become more commercially viable. Companies like 3D Systems, founded by Chuck Hull, began selling SLA-based 3D printers. Several key patents related to 3D printing technologies were also granted during this period.

- 2000s – Diversification and Open Source: The 3D printing industry diversified further during the 2000s. Open-source 3D printing projects like RepRap emerged, allowing enthusiasts to build and modify their 3D printers. This open-source movement contributed to the democratization of 3D printing technology.

- 2010s – Mainstream Adoption: The 2010s saw 3D printing technology becoming more mainstream. 3D printers became more affordable, and various industries began adopting the technology for rapid prototyping, customization, and even some production applications. Companies like MakerBot brought 3D printing to the consumer market.

- Advanced Materials and Applications: Throughout the decade, there were significant advancements in 3D printing materials, including metals, ceramics, and composites. This expanded the range of industries that could benefit from 3D printing, such as aerospace, healthcare, and automotive.

- Large-Scale and Continuous Printing: New technologies emerged, enabling large-scale 3D printing and continuous printing, where entire structures or buildings could be 3D printed layer by layer. This development had implications for architecture and construction.

- Bioprinting and Medical Applications: Bioprinting, a subfield of 3D printing, gained prominence in the medical and healthcare sectors. Researchers began experimenting with printing human tissues, organs, and implants.

- 2020s and Beyond: 3D printing technology continued to evolve rapidly. The industry was exploring new methods and materials, including 4D printing, which involves printed objects that can change shape or properties over time. 3D printing was also being used in response to global challenges like the COVID-19 pandemic for producing medical equipment and supplies.

The history of 3D printing is a story of innovation, from its early beginnings as experimental technology to its integration into various industries and its potential to revolutionize manufacturing and customization in the future. it’s likely that there have been further advancements and applications in the field of 3D printing.

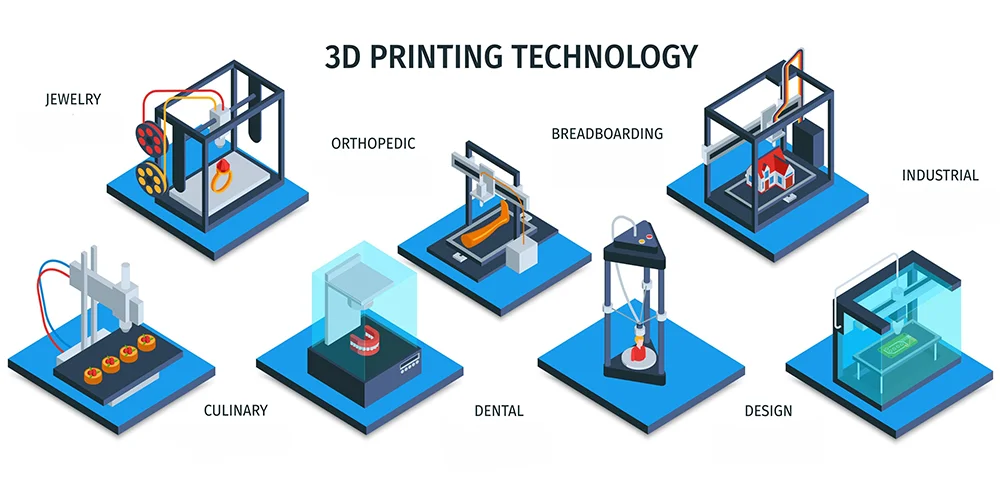

Types of 3D Printing Technology

There are several types of 3D printing technologies, each with its own unique approach to creating three-dimensional objects. These technologies differ in terms of the materials they use, the printing processes, and their applications.

Here are some of the most common types of 3D printing technology:

- Stereolithography (SLA):

– SLA was one of the earliest 3D printing technologies developed.

– It uses a UV laser to cure layers of liquid photopolymer resin.

– SLA is known for its high-resolution and accuracy, making it suitable for intricate and detailed models.

– Commonly used in industries like jewelry, dentistry, and prototyping. - Fused Deposition Modeling (FDM):

– FDM is one of the most popular and widely used 3D printing technologies.

– It works by extruding thermoplastic filament through a heated nozzle to build up layers.

– FDM printers are known for their affordability and accessibility.

– Applications include rapid prototyping, custom manufacturing, and hobbyist use. - Selective Laser Sintering (SLS):

– SLS uses a high-powered laser to sinter (fuse) powdered materials, typically plastics, metals, or ceramics.

– This technology is known for producing strong, functional parts with good mechanical properties.

– Widely used in aerospace, automotive, and industrial applications. - Multi Jet Fusion (MJF):

– MJF is another powder-based 3D printing technology.

– It uses an inkjet array to selectively apply fusing and detailing agents to a powdered material bed.

– MJF is known for its speed and ability to produce detailed parts with consistent mechanical properties.

– Applications include manufacturing and production parts. - PolyJet Printing:

– PolyJet technology works by jetting thin layers of liquid photopolymer onto a build tray and curing them with UV light.

– It can produce parts with multiple materials and a wide range of colors.

– Often used for creating highly detailed and realistic prototypes and models. - Digital Light Processing (DLP):

– DLP 3D printing uses a digital light projector to cure entire layers of resin at once.

– It offers speed and high-resolution printing.

– Commonly used for dental applications, jewelry, and consumer products. - Binder Jetting:

– Binder jetting involves selectively depositing a liquid binding agent onto a powdered material, such as metal or sand.

– It is used in both metal and sand casting processes for rapid prototyping and tooling applications. - Electron Beam Melting (EBM):

– EBM is primarily used for 3D printing metal parts.

– It uses an electron beam to melt and fuse metal powder layer by layer.

– EBM is known for producing high-strength, complex metal parts used in aerospace and medical industries. - Directed Energy Deposition (DED):

– DED technology involves depositing material (usually metal wire or powder) through a nozzle while simultaneously melting it with a laser or electron beam.

– Used for repairing and adding material to existing parts or for creating large-scale structures. - Bioprinting:

– Bioprinting is a specialized 3D printing technology used to create three-dimensional biological structures, such as tissue and organs.

– It utilizes bioinks containing living cells and biomaterials.

– Bioprinting has applications in regenerative medicine and pharmaceutical research.

These are some of the most prominent 3D printing technologies, each with its strengths and applications across various industries. The choice of technology depends on factors like material requirements, accuracy, speed, and the specific needs of the project or application.

Benefits of 3D Printing Technology

3D printing technology offers a wide range of benefits, which have contributed to its rapid growth and adoption across various industries.

Here are some of the key advantages of 3D printing:

- Rapid Prototyping: 3D printing allows for the quick and cost-effective production of prototypes and design iterations. This speeds up product development and reduces time-to-market.

- Customization: It enables the creation of highly customized and one-of-a-kind products. This is particularly valuable in industries like healthcare for creating patient-specific medical implants and prosthetics.

- Complex Geometry: 3D printing can produce complex and intricate geometries that are difficult or impossible to achieve with traditional manufacturing methods. This opens up new design possibilities.

- Reduced Waste: Traditional subtractive manufacturing processes often generate significant waste as material is cut away. 3D printing is more material-efficient since it adds material only where needed, reducing waste.

- On-Demand Manufacturing: 3D printing enables on-demand and localized manufacturing. This reduces the need for extensive warehousing and long supply chains, contributing to sustainability.

- Cost-Effective for Small Batches: It is cost-effective for producing small quantities of parts or products. This is beneficial for small and medium-sized businesses that may not have the resources for mass production.

- Design Iteration: Engineers and designers can easily iterate and refine their designs without the cost and time associated with traditional tooling changes.

- Low Tooling Costs: Unlike traditional manufacturing, which often requires expensive molds and tooling, 3D printing doesn’t have these upfront costs, making it accessible to a wider range of applications.

- Reduced Lead Times: 3D printing can significantly reduce lead times for producing parts and products. This is particularly valuable for industries with time-sensitive needs.

- Digital Inventory: With 3D printing, companies can maintain digital inventories of their products and produce items as needed, reducing the need for physical warehousing.

- Material Variety: There is a wide range of materials available for 3D printing, including plastics, metals, ceramics, and composites, allowing for versatility in applications.

- Innovation and Experimentation: 3D printing fosters innovation and experimentation across various industries, encouraging the development of novel products and solutions.

- Accessibility: Desktop 3D printers have become more affordable and accessible, making the technology available to hobbyists, educational institutions, and small businesses.

- Reduced Risk: 3D printing allows for the creation of prototypes and test parts before committing to full-scale production, reducing the risk of costly errors.

- Medical Applications: In healthcare, 3D printing has enabled the creation of patient-specific implants, surgical guides, and anatomical models, leading to improved patient outcomes.

- Aerospace and Automotive: These industries benefit from lightweight and optimized components, rapid prototyping, and reduced lead times enabled by 3D printing.

- Sustainability: 3D printing’s material-efficient and on-demand production can contribute to sustainability efforts by reducing waste and energy consumption.

Overall, 3D printing technology has revolutionized manufacturing and design processes, offering a multitude of advantages that continue to drive innovation and transformation in various sectors. Its potential applications continue to expand as new materials and technologies are developed.

How does 3D printing save the environment?

3D printing has the potential to contribute to environmental conservation and sustainability in several ways:

- Reduced Material Waste: Traditional subtractive manufacturing processes often involve cutting, milling, or carving away material from a larger piece, generating significant waste. In contrast, 3D printing is an additive manufacturing process, which means it adds material layer by layer, using only the amount required to build the object. This reduces material waste and minimizes environmental impact.

- Energy Efficiency: Some 3D printing technologies, especially those that use thermoplastics or photopolymers, can be more energy-efficient than traditional manufacturing methods. For example, in selective laser sintering (SLS), only the areas where the material is sintered receive heat, reducing overall energy consumption compared to traditional high-heat processes.

- Localized Production: 3D printing enables localized and on-demand production. Products can be manufactured closer to where they are needed, reducing the energy and emissions associated with long-distance shipping and transportation. This can also contribute to the reduction of greenhouse gas emissions.

- Lightweighting: 3D printing allows for the design and production of lightweight and optimized components. In industries like aerospace and automotive, this can lead to reduced fuel consumption due to lighter vehicle or aircraft structures.

- Design Optimization: 3D printing enables the creation of complex and optimized designs that were previously impractical or impossible to produce using traditional manufacturing methods. These designs often result in more efficient and resource-saving products.

- Sustainable Materials: Researchers are developing sustainable and eco-friendly materials for 3D printing, such as biodegradable plastics, recycled filaments, and bio-based resins. These materials reduce the environmental impact of 3D printing even further.

- Product Longevity: 3D printing can be used for repair and maintenance, extending the lifespan of products. This reduces the need for new manufacturing and decreases the number of items ending up in landfills.

- Customization and Local Manufacturing: By enabling customization and small-batch production, 3D printing can reduce overproduction and excess inventory, which is a common issue in traditional manufacturing.

- Reduced Tooling: Traditional manufacturing often requires the creation of molds and tooling, which can be resource-intensive and result in waste when design changes are needed. 3D printing eliminates the need for most of these tools.

- Sustainable Architectural Practices: In construction, large-scale 3D printing can use eco-friendly materials and reduce construction waste by producing only the necessary amount of building material.

While 3D printing offers several environmental benefits, it’s important to note that the overall environmental impact of 3D printing can vary depending on factors such as the materials used, the energy source for the printers, and the scale of production. Therefore, to maximize its environmental benefits, it’s essential to consider material choices, energy efficiency, and sustainable practices when implementing 3D printing technologies.

How 3D printing will change the future?

3D printing has the potential to bring about significant changes and innovations in various aspects of the future.

Here are some ways in which 3D printing is expected to impact and transform the future:

- Customization and Personalization: 3D printing will enable highly customized and personalized products, ranging from consumer goods and fashion to healthcare products like custom orthopedic implants and dental devices. This shift toward personalization will empower individuals to have greater control over the design and functionality of the products they use.

- Rapid Prototyping and Product Development: 3D printing will continue to accelerate product development processes by allowing companies to quickly iterate and test designs. This will reduce time-to-market and enable more efficient innovation in industries ranging from aerospace to consumer electronics.

- Reduced Material Waste: As an additive manufacturing technology, 3D printing minimizes material waste by adding material only where needed. This reduction in waste will contribute to sustainability efforts and reduce the environmental impact of manufacturing.

- On-Demand and Local Manufacturing: 3D printing will enable on-demand and localized manufacturing, reducing the need for extensive warehousing and long-distance transportation. This will lead to more sustainable and efficient supply chains.

- Complex Geometries: The ability of 3D printing to produce intricate and complex shapes will drive innovations in industries such as architecture, automotive, and aerospace, where lightweight and optimized structures are crucial.

- Healthcare Revolution: 3D printing will play a pivotal role in the healthcare industry by producing patient-specific medical implants, prosthetics, and anatomical models. This will improve patient outcomes, reduce healthcare costs, and advance medical research.

- Education and Training: 3D printing will be integrated into educational curricula, allowing students to gain hands-on experience in design, engineering, and manufacturing. It will also provide medical professionals with realistic surgical training tools.

- Space Exploration: 3D printing will be used to manufacture tools, parts, and even habitats on distant planets, making space exploration more self-sufficient and sustainable.

- Art and Design: Artists and designers will continue to explore the creative possibilities of 3D printing, pushing the boundaries of art and design with novel and unique creations.

- Consumer Adoption: As 3D printers become more affordable and user-friendly, they will become common household appliances. Consumers will be able to print replacement parts, custom home decor, and other items at home.

- Sustainable Practices: 3D printing’s reduced waste, efficient material usage, and localized production will contribute to sustainable manufacturing practices and support circular economies.

- Supply Chain Resilience: 3D printing can help companies mitigate disruptions in their supply chains by allowing them to produce critical parts and products on-site during emergencies or shortages.

- Regenerative Medicine: Bioprinting, a subset of 3D printing, will advance the field of regenerative medicine by enabling the printing of functional tissues and organs for transplantation.

- Aerospace and Defense: 3D printing will continue to revolutionize aerospace and defense manufacturing by producing lightweight and high-performance components, leading to more fuel-efficient aircraft and more capable defense systems.

- Construction: Large-scale 3D printing will be used to construct buildings and infrastructure, reducing construction waste and time while enabling innovative architectural designs.

In summary, 3D printing is poised to reshape industries, drive innovation, and enhance sustainability in the future. Its versatility and ability to address various challenges make it a transformative technology with profound implications for manufacturing, healthcare, education, and beyond. As the technology evolves and becomes more accessible, it will continue to unlock new possibilities and revolutionize the way we create and interact with objects in the world.

Cloud Computing: Definition, Types, Scope, & Benefits